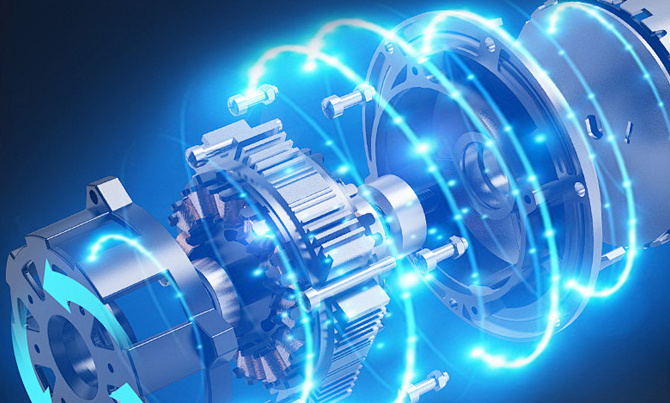

Installation of electromagnetic speed regulating motor

Preparation before 1. installation

Before installing the speed regulating motor, check whether the package is intact and damp. After opening the cover, carefully remove the dust and rust-proof layer on the motor. Carefully check whether there is deformation and damage during transportation, whether the fasteners are loose or fall off, whether the rotor rotates flexibly, whether the nameplate data meets the requirements. Measure the high voltage resistance with 500VMQ meter. The insulation resistance should not be less than 1MQ. Otherwise, the winding should be dried, however, the treatment temperature does not exceed J20 °C.

Installation site and installation foundation of 2. electromagnetic speed regulating motor

The altitude of the installation site of the speed regulating motor shall not exceed 1000m; The installation site of the general-purpose motor shall be dry and clean, the surrounding area of the motor shall be well ventilated, and a certain interval shall be left with other equipment to facilitate inspection, monitoring and cleaning. The ambient temperature shall be below 40 ℃, and strong radiation shall be prevented. The installation foundation shall be firm and firm, with certain rigidity, and the installation surface shall be flat, to ensure the balanced operation of the motor.

3. electromagnetic speed motor installation matters needing attention

1, speed motor should be properly grounded, the junction box in the lower right and base shell grounding device, if necessary, can also use speed motor foot or flange fastening bolt grounding, to ensure the safe operation of the speed motor.

2. Connection between motor and mechanical load

① The speed regulating motor can adopt coupling, and the normal gear shaft or belt is mechanically connected with the load. The fan end of the double shaft extension motor is only allowed to use coupling transmission.

When the coupling is used, the center line of the motor shaft should coincide with the center line of the load machine, so as to avoid strong vibration, linkage and abnormal sound of the motor in motion.

③ vertical installation of electromagnetic speed motor, shaft extension only allow the use of coupling and mechanical load connection.

3. Check before starting the motor

Newly installed or disabled for more than three months before the start of the speed motor should check the insulation resistance, the measured insulation resistance value is not less than 1MQ, check whether the fastening screws of the motor are tightened, whether the bearing is short of oil, whether the wiring of the motor meets the requirements, Whether the shell is reliably grounded or connected to zero. Check whether the screws and pins of the coupling are tightened, whether the belt connection is good, whether the tightness is appropriate, whether the unit rotates flexibly, whether there is any clamping, movement and abnormal sound, etc. Check whether the rated current of the fuse meets the requirements and whether the installation is firm and reliable. Check whether the wiring of the starting equipment is correct, whether the starting device is flexible, whether the contact point is in good condition, and whether the metal shell of the starting equipment is reliably grounded or connected to zero. Check whether the three-phase power supply voltage is normal, whether the voltage is too high or too low, or the three-phase voltage is asymmetric, etc.